CTS-02V4(Concrete Test and Surveyor)

Non-destructive testing equipment for primary screening

CTS-02v4 was developed after the collapse at a railroad tunnel in 1999. Existing inspection methods were insufficient to assess the condition of concrete in terms of measurement accuracy, convenience of data analysis, objectivity and traceability of measured data. CTS-02v4 is an ideal non-destructive testing equipment to solve these issues. Estimated compressive strength of target concrete will displayed on the display right after the hammer blow, and the data can be transferred to your PC with USB connection.

Contents

1.Applications

2.Comparison

3.Specification

4.How to Use

5.Basic Principle

6.Typical Measured Waveforms

2.Comparison

3.Specification

4.How to Use

5.Basic Principle

6.Typical Measured Waveforms

Applications

〇Estimation for compressive strength of concrete (Normal to High strength concrete)

〇Detecting degree of degradation of concrete surface

〇Detecting delamination of concrete surface

〇Detecting aggregate pop-out

〇Detecting degree of degradation of concrete surface

〇Detecting delamination of concrete surface

〇Detecting aggregate pop-out

Comparison

Comparison on Estimation of Compressive Strength

CTS

Rebound hammer

Estimation accuracy

※Comparison with compression test as 100% based on our experiment

※Comparison with compression test as 100% based on our experiment

85%

50%

Applicable range of strength

10~150N/mm2

10~70N/mm2

Data correction

Unnecessary

Necessary

Number of measurement point

3250 point/day

1500 point/day

Data analysis

6375 point/day

1000 point/day

Comparison on detection of delamination of concrete

CTS

Inspection hammer (hammer sounding test)

Judgement criteria

Objective

Subjective

Data output

CSV (digital)

Paper (analog)

Specifications

Model Name

CTS-02V4(Concrete Test and Surveyor)

Applicable Standard

NDIS3434-3

Storage case dimensions

390mm x 255mm x 120mm

Body size

108mm x 69mm x 42mm

Hammer Weight

380g

Waveform Measurement

Sampling clock: 0.5µs, Measuring time: 2 ms

Power supply

AA Batteries x 4 (for 12 hours)

Connection to PC

USB

Number of measurement data

Up to approx. 500,000

Accessories

USB cable(A - mini B)

Strap

Storage case

AA batteries x 4

CD-ROM (Application software, device driver, User manual)

Strap

Storage case

AA batteries x 4

CD-ROM (Application software, device driver, User manual)

How to Use

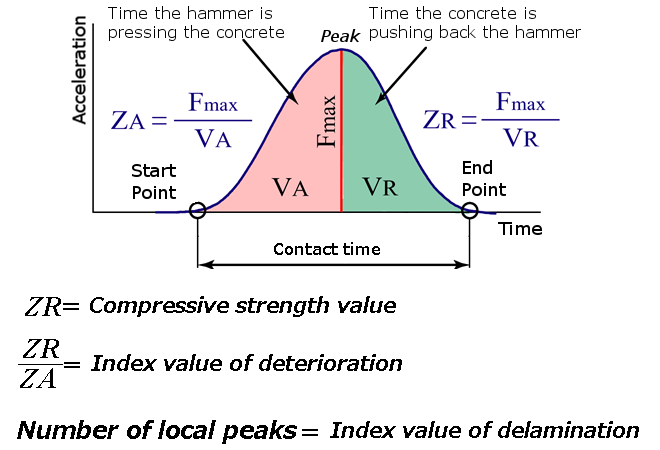

Basic Principle

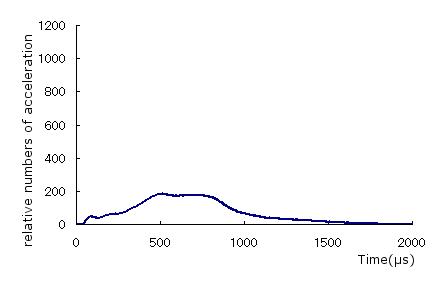

The waveform of impact force in below is obtained by tapping concrete with CTS. This wave form is measured by an accelerometer that installed on the hammer unit. Measured wave form can be divided into two part. The first half of the waveform shows the process that the hammer is pushing on the concrete surface. This process includes plastic deformation first, then elastic deformation of concrete surface. The second half of the waveform is the process that the hammer is rebounding from the concrete surface. In other words, the second half of the waveform is only affected by the characteristics of elasticity of concrete, and compressive strength of the concrete that is not affected by deterioration of concrete surface can be estimated. Besides, degree of deterioration of concrete surface can be determined from the ratio of the first half and the second half of the waveform.

Typical Measured Waveforms

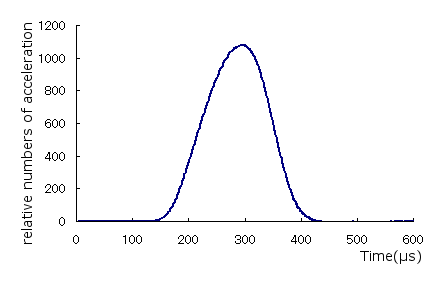

●Measured waveform of sound concreteThe shape of waveform will be symmetry. Since concrete is not perfectly elastic body, first half of the waveform shall contain an influence of elasticity of surface layer.

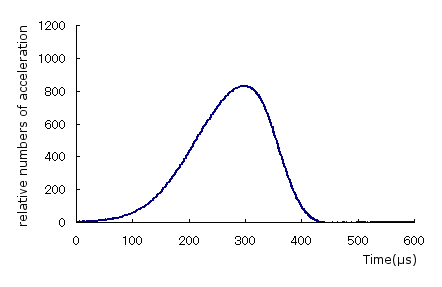

●Measured waveform of concrete with degraded surfaceFirst half of the waveform will be longer comparing to sound concrete. In this case, first half of the waveform contains an influence of elastic deformation of degraded concrete surface while it is reduced in the second half of the waveform.

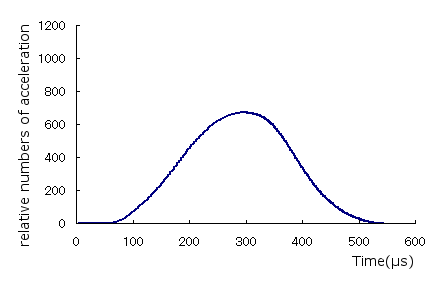

●Measured waveform of concrete with delamination near the surface (1)

This type of waveform will be measured when delamination is occurred near the surface. The shape of waveform seems like a sound concrete, but peak of the waveform becomes lower and contact time of the hammer becomes longer. As the delaminated concrete surface reacts like a blade spring against hammer blow, maximum impact becomes lower and contact time becomes longer.

●Measured waveform of concrete with delamination near the surface (2)

When the concrete is seriously damaged (delaminated), decent waveform cannot be measured.