BOLT-Tester

Non-destructive testing equipment for primary screening

BTS(BOLT-Tester) is developed in 2012 after the collapse at SASAGO Tunnel on the Chuo Expressway in Japan. Visual inspection and hammer sound testing are main inspection methods for maintenance and management of anchor bolts in a tunnel. However, these methods have some issues in regard to objectivity and reliability of the results. Pull out testing is also one of a testing method for the soundness test of anchor bolts, however, this method have also some issues in regard to cost and time, and there is a risk to damage the anchor bolt. BTS is simple and cost effective non-destructive testing equipment that solves those issues. BTS measures a waveform of impact force to evaluate the soundness of anchor bolt.

Contents

1.Applications

2.Size of hammer

3.Specification

4.How to Use

5.Basic Principle

6.Typical Measured Waveforms

2.Size of hammer

3.Specification

4.How to Use

5.Basic Principle

6.Typical Measured Waveforms

Applications

〇Soundness testing for post-installed anchor bolt

〇Looseness testing for bolts and nuts

〇Looseness testing for wheel bolts

〇Looseness testing for bolts and nuts

〇Looseness testing for wheel bolts

Size of hammer

It is recommended to change the size of hammer according to the size of object to be measured.

BOLT-Tester(Large) (Left) ⇒ Weight: 1,400g Target size: M20 to M24

BOLT-Tester(Standard) (Center)⇒ Weight: 420g Target size: M12 to M20

BOLT-Tester(Small) (Right) ⇒ Weight: 190g Target size: M8 to M12

BOLT-Tester(Large) (Left) ⇒ Weight: 1,400g Target size: M20 to M24

BOLT-Tester(Standard) (Center)⇒ Weight: 420g Target size: M12 to M20

BOLT-Tester(Small) (Right) ⇒ Weight: 190g Target size: M8 to M12

Specification

Model Name

BOLT-Tester

Applicable Standard

NETIS (HK-180001-A)

Storage case dimensions

390mm x 240mm x 130mm

Device

106mm x 40mm x 11mm

①Weight of Hammer (Large)

②Weight of Hammer (Standard)

③Weight of Hammer (Small)

②Weight of Hammer (Standard)

③Weight of Hammer (Small)

①1,400g

②420g

③190g

②420g

③190g

Waveform Measurement

Sampling clock: 0.5µs, Measuring time: 2 ms

Power supply

Bus-powered (up to 350mA)

Connection to PC

USB connection with Windows PC

Measurement data

Recorded as a text format

Accessories

Storage case

USB cable (A-A male-female, 1m)

CD-ROM(Device driver, application and user manual)

USB cable (A-A male-female, 1m)

CD-ROM(Device driver, application and user manual)

How to use

Basic Principle

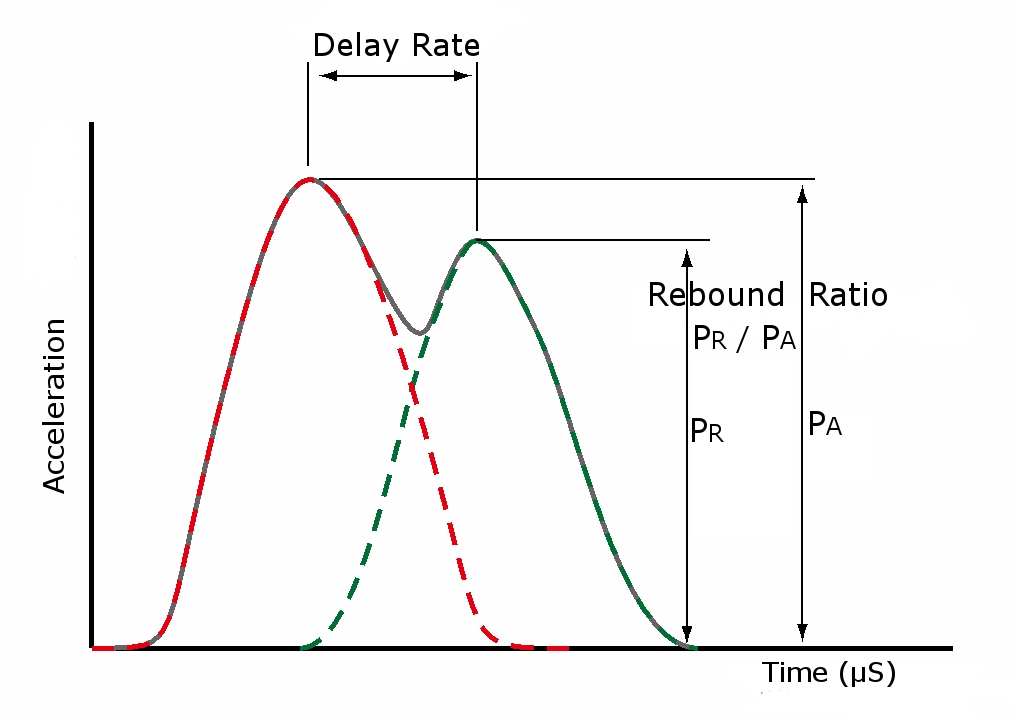

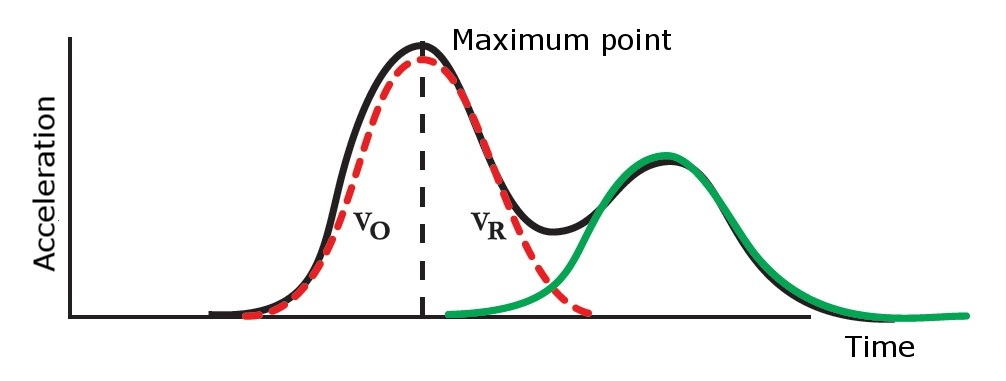

When an anchor bolt is correctly installed, the bolt behaves elastically and back to original position after the impact by the hammer. The more a bolt is firmly installed, the more the impedance (modulus of elasticity) becomes large. On the other hand, in case the bolt is not firmly installed, modulus of elasticity becomes lower and measured waveform will be disturbed. Moreover, adhesion becomes more lower, the bolt moves and strikes concrete, and measured waveform becomes two peaks. BOLT-Tester evaluates soundness of an anchor bolts by analyzing the measured waveform.

Example of the waveform

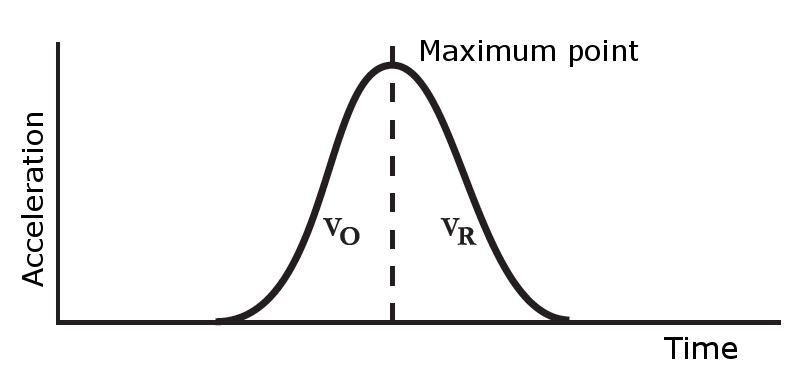

●Waveform of stable anchor bolt

Measured waveform becomes most likely symmetry. Shape of the waveform becomes slightly disturbed depending on the condition of target bolt, number of peak is only one.

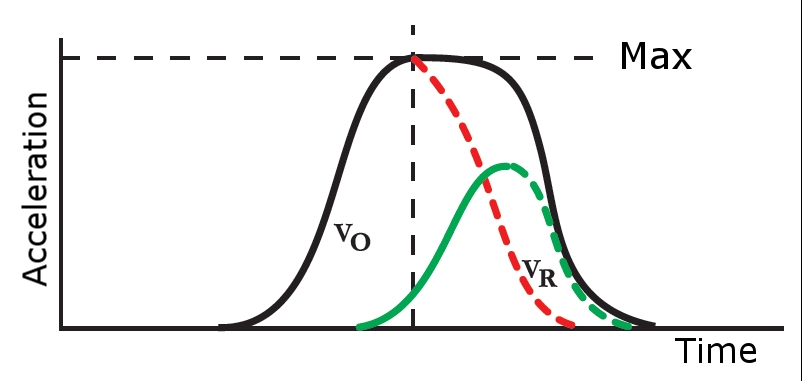

●Waveform of a bit deformed anchor bolt

Peak of the waveform becomes wider as a response from the bolt is delayed.

●Waveform of loose anchor bolt

Peak of the waveform becomes two due to the delay in a response from the bolt.